Basic Principles of LED

Light-emitting diodes(LEDs) are optoelectronic components made of three-five group compoundsemiconductors, whose core is a PN junction. Under the forward voltage,electrons are injected into the P zone from the N zone, and holes are injectedinto the N zone from the P zone. Some of the minority carriers and the majoritycarriers that enter the opposing area recombine and emit light. The nature ofthe material forming the PN junction (band gap) determines the wavelength ofthe emitted light. For visible light, it determines the color of the light.

The main features of LED are: small size, low powerconsumption, long service life, high brightness and low heat, environmentalprotection and durability. Working under proper current and voltage, the lifeof LED can be as long as 100,000 hours.

LED classification andapplication

According to the type oflight emitted, LEDs can be divided into visible light LEDs and invisible lightLEDs.

Visible LEDs include red,orange, yellow, green, blue, and violet LEDs. Among them, red LED materials aremainly GaP (binary system), AlGaAs (ternary system) and AlGaInP (quaternarysystem); blue/white LED materials are mainly GaN.

LED applications are veryextensive, mainly including:

1. LED display: indoorand outdoor billboards, sports scoreboards, information display screens, etc.;

2. Signal indicator:Intra-city traffic lights, highway, railway and airport signal lights,electronic equipment function instructions in major and medium cities acrossthe country;

3, light color lighting:outdoor landscape lighting and indoor decorative lighting;

4. Special general lighting: portablelighting (flashlights, headlights), low-light lighting (gallery lights, houselights, court lights), reading lighting (reading lights for airplanes, trains,and cars), microscope lights, camera flashes, desk lamps , Street lights;

5. Safety lighting: miner'slamp, explosion-proof lamp, emergency lamp, safety indicator lamp;

6. Backlight source: LCDmonitor, LCD TV backlight source.

7. Automotive lights: including interiorlighting and exterior lighting. The interior of the car includes dashboard,electrical product indicator lights (switches, audio, etc.), switch backlight,reading lights, and external brake lights, tail lights, side lights and headsLights etc.

8. Other applications:consumer use, such as children's flash shoes, Christmas tree LED lights, etc.

LED Industry Chain

The entry barrier of theLED industry chain from upstream to downstream industries is gradually lowered.The upstream is single wafer and its epitaxy, the midstream is LED chipprocessing, and the downstream is packaging testing and application. Among them,the upstream and midstream have high technology content and high capitalinvestment density, making them the areas with the most intense internationalcompetition and the greatest operational risks. In the LED industry chain, LEDepitaxial wafers and chips account for about 70% of the industry's profits, LEDpackaging accounts for about 10-20%, and LED applications also account forabout 10-20%.

Single wafer is the basefor manufacturing LEDs, also called substrates, mostly using sapphire, siliconcarbide, GaAs, and GaP as materials. The epitaxial wafer is to grow multiplelayers of single crystal films of different thicknesses on a single crystal,such as AlGaAs, AlGaInP, GaInN, etc., to realize LEDs of different colors orwavelengths. Common epitaxy methods include liquid phase epitaxy (LPE), vaporphase epitaxy (VPE), and metal organic chemical vapor deposition (MOCVD), amongwhich VPE and LPE technologies are quite mature and can be used to grow generalbrightness LEDs. The MOCVD method must be used to grow high-brightness LEDs. Atpresent, the main global MOVCD manufacturers are Germany's AIXTRON company andAmerican VEECO company. The former accounts for about 60% to 70% of theinternational market share, and the latter accounts for 30% to 40%. Equipmentproduced by Japanese manufacturers is basically limited to sales in Japan.

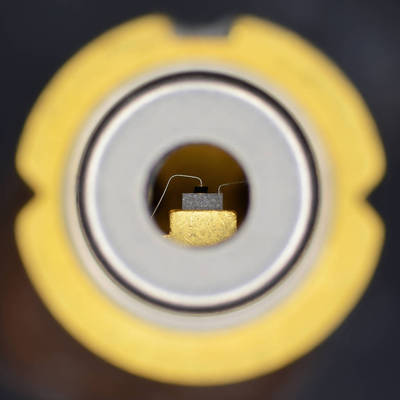

Midstream is mainly chipdesign and processing. Midstream manufacturers carry out device structure andprocess design according to the performance requirements of LEDs, throughepitaxial wafer diffusion, then metal coating, photolithography, heat treatment,forming metal electrodes, and then the substrate is thinned and polished beforecutting.

The downstream includesthe packaging test and application of LED chips. LED packaging refers toconnecting the outer leads to the electrodes of the LED chip to form an LEDdevice. The packaging plays a role in protecting the LED chip and improving theefficiency of light extraction. LED packaging technology is developed from thepackaging technology of semiconductor discrete devices. At present, thepackaging types of LED products mainly include Lamp type, plug-in type(ThroughHole), surface mount type (SMD), direct bonding type (DirectBonding),etc. Among them, SMD LEDs are smaller than other traditional LEDs, so SMD LEDsare mainly used for mobile phone screen backlights and mobile phone buttons,which are greatly affected by mobile phone demand.

led beads,led beads types,led light beads,small led lights

It is forbidden to use the above content without theauthor's authorization, and reprinting must note the source of this content orthe consent of the publisher

Source: Queendom Technology Co., Ltd. Author:JACKY date: 2020 May 22

English

English china

china German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian

Mobile Site

Mobile Site

+86-0769-81305858

+86-0769-81305858